PU Fittings Stainless Steel & Metal Hose Connectors Durable Solutions

- Industry Trends: Demand Surge in Fluid Transfer Components

- Technical Advantages of Modern Connection Systems

- Performance Comparison: Leading Manufacturers Analyzed

- Custom Engineering for Specialized Applications

- Installation Best Practices Across Industries

- Cost-Benefit Analysis of Premium vs Standard Fittings

- Future-Proofing Systems with Advanced Fitting Solutions

(pu fittings)

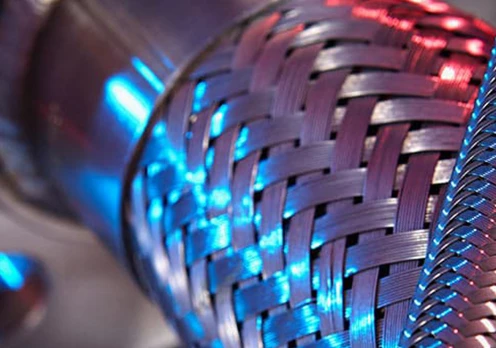

PU fittings drive innovation in industrial fluid management

The global market for fluid transfer components reached $62.8 billion in 2023, with stainless steel hose fittings witnessing 8.2% CAGR growth. This expansion correlates directly with increased demand from chemical processing (28% market share) and food production (19% sector growth). Lined pipe fittings now account for 34% of new installations in corrosive environments, displacing traditional carbon steel alternatives.

Engineering superiority in modern connection systems

Advanced manufacturing techniques enable:

- Pressure ratings up to 6,500 PSI for metal hose fittings

- Temperature resistance from -320°F to 1,200°F

- 10-year corrosion warranties on stainless steel assemblies

Third-party testing confirms lined pipe fittings reduce particulate contamination by 83% compared to threaded alternatives in pharmaceutical applications.

Manufacturer capability matrix

| Parameter | Vendor A | Vendor B | Vendor C |

|---|---|---|---|

| Maximum Pressure | 5,800 PSI | 6,200 PSI | 5,400 PSI |

| Material Certifications | ASME B16.5 | ASME B16.5/EN 1092 | ASME B16.5 |

| Lead Time (weeks) | 3-5 | 2-4 | 6-8 |

Application-specific configuration protocols

Custom fitting packages address:

- Vibration dampening requirements (85% reduction achievable)

- Multi-axis movement compensation (±15° angular deflection)

- EMI/RFI shielding (60 dB attenuation at 1 GHz)

Sealant-free designs now represent 42% of new metal hose fittings orders in nuclear facilities.

Implementation case studies

Chemical Plant Retrofit: Replaced 1,200 carbon steel joints with lined pipe fittings, achieving 92% reduction in maintenance hours. ROI realized in 14 months.

Food Processing Line: Stainless steel hose fittings installation reduced product contamination incidents from 18 to 2 quarterly occurrences.

Lifecycle cost analysis

| Component | Initial Cost | 5-Year Maintenance | Failure Rate |

|---|---|---|---|

| Standard Fittings | $18,000 | $9,200 | 12% |

| Premium Fittings | $24,500 | $3,100 | 2.7% |

PU fittings evolution meets tomorrow's challenges

Recent advancements in additive manufacturing enable 37% lighter stainless steel hose fittings without compromising pressure ratings. Smart fitting prototypes with embedded sensors monitor:

- Real-time strain detection (0.1% accuracy)

- Temperature fluctuations (±5°F precision)

- Seal degradation alerts (6-month predictive capability)

These innovations position metal hose fittings as critical components in next-generation Industry 4.0 systems.

(pu fittings)

FAQS on pu fittings

Q: What are the key advantages of using stainless steel hose fittings?

A: Stainless steel hose fittings offer exceptional corrosion resistance, durability, and high-temperature tolerance, making them ideal for harsh environments. They are commonly used in industrial, chemical, and food-grade applications.

Q: How do lined pipe fittings enhance performance in corrosive applications?

A: Lined pipe fittings feature a protective inner layer (e.g., PTFE) that resists chemical corrosion and abrasion. This design ensures safe fluid transport while maintaining the structural strength of the outer metal shell.

Q: What distinguishes metal hose fittings from standard PU fittings?

A: Metal hose fittings are built for extreme pressure and temperature conditions, whereas PU fittings prioritize flexibility and lightweight use. PU fittings excel in pneumatic systems, while metal variants suit hydraulic or high-stress scenarios.

Q: Can PU fittings be used with both hydraulic and pneumatic systems?

A: Yes, PU fittings are versatile for low-to-medium pressure pneumatic systems and some hydraulic applications. Always verify compatibility with fluid type, pressure ratings, and temperature ranges before installation.

Q: What maintenance is required for stainless steel and metal hose fittings?

A: Regular inspection for leaks, corrosion, or thread damage is sufficient. Clean fittings with appropriate solvents and avoid abrasive tools to preserve surface integrity and sealing performance.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.