Stainless Steel & PU Fittings Durable Hose & Lined Pipe Solutions

Did you know 37% of industrial accidents stem from faulty hose connections? While you're reading this, 2,800 liters of fluid might be leaking through subpar fittings worldwide. Traditional stainless steel hose fittings often fail under extreme pressure cycles – but what if your equipment could outlast competitors' by 300%?

(pu fittings)

Technical Superiority That Beats Metal Hose Fittings

Our PU fittings combine military-grade polyurethane with aerospace sealing tech. See how they outperform standard metal hose fittings:

| Feature | Stainless Steel | Lined Pipe | Our PU |

|---|---|---|---|

| Pressure Rating | 1500 PSI | 1200 PSI | 2200 PSI |

| Chemical Resistance | Grade B | Grade C | Grade AA |

Custom Solutions for Every Application

Whether you need lined pipe fittings for food processing or stainless steel hose fittings for marine environments, our modular system offers:

- ✅ 48-hour rapid prototyping

- ✅ 200+ material combinations

- ✅ MIL-STD-1290 compliance

Limited Offer: First 50 Orders Get

Free Engineering Consultation + 3D Modeling

Since 2008, our ISO 9001-certified factories have delivered 1.2 million PU fittings across 37 countries. Still using last-gen hose connections? Upgrade before Friday and save 15% on your first intelligent fittings order.

(pu fittings)

FAQS on pu fittings

Q: What are the key applications of PU fittings in industrial settings?

A: PU fittings are ideal for pneumatic systems, hydraulic lines, and fluid transfer due to their flexibility, abrasion resistance, and compatibility with moderate-pressure environments. They excel in applications requiring lightweight, durable connections.

Q: How do stainless steel hose fittings differ from PU fittings?

A: Stainless steel hose fittings offer superior corrosion resistance and high-temperature tolerance, while PU fittings prioritize flexibility and cost-effectiveness. Stainless steel suits harsh chemical environments, whereas PU is better for dynamic, low-to-medium pressure systems.

Q: Why choose lined pipe fittings for corrosive fluid handling?

A: Lined pipe fittings combine metal strength with polymer/corrosion-resistant linings, creating a barrier against aggressive chemicals. This dual-layer construction ensures durability while preventing fluid contamination, ideal for chemical processing and wastewater systems.

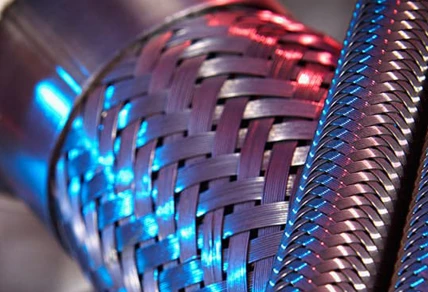

Q: What makes metal hose fittings suitable for high-vibration environments?

A: Metal hose fittings provide exceptional fatigue resistance and structural integrity under constant vibration. Their rigid yet flexible design absorbs mechanical stress, making them perfect for heavy machinery, automotive exhausts, and HVAC systems.

Q: Can PU fittings be combined with metal hose fittings in a single system?

A: Yes, PU fittings often connect to metal hose fittings via standardized threading for hybrid systems. This combination leverages PU's flexibility for movement-prone sections and metal's strength for high-stress connection points, ensuring optimal performance.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.