PVC Coated Metal Flexible Conduit Flexible, Drustproof Protection

Did you know 43% of industrial electrical failures stem from substandard conduit corrosion? Or that factories waste $18,000/year on average replacing cracked wiring protectors? Your operations demand PVC coated metal flexible conduit that outperforms – not just survives.

(pvc coated metal flexible conduit)

Why Our PVC Coated Flexible Conduit Outperforms Competitors

Imagine conduit that laughs at salt spray tests (passed 1,200+ hours), bends like gymnasts (180° rotation), and costs 22% less than steel counterparts. Our PVC coated flexible pipe delivers:

- 3X abrasion resistance vs. standard PVC (ASTM D3389-16 verified)

- -40°F to 212°F operational range

- 20-year anti-corrosion warranty

Head-to-Head: Conduit Showdown

| Feature | Our Model X7 | Brand B | Brand C |

|---|---|---|---|

| Price per meter | $4.90 | $6.20 | $5.80 |

| Warranty | 20 years | 12 years | 15 years |

| Bend Radius | 4x OD | 6x OD | 5x OD |

Your Custom Conduit, Built in 72 Hours

Need UV-resistant PVC conduit flexible pipe for solar farms? Flame-retardant versions for chemical plants? Our modular system ships custom orders faster than Amazon Prime.

Proven in Battle: Auto Plant Case Study

When a Detroit assembly line reduced conduit replacement costs by 68% using our solution, their maintenance chief said: "This is the last conduit we'll ever buy."

Ready to slash maintenance budgets and boost uptime? As North America's 1 UL-certified flexible conduit maker since 2008, we guarantee 24-hour tech support and 100% defect-free delivery. Claim Your Free Sample Kit →

(pvc coated metal flexible conduit)

FAQS on pvc coated metal flexible conduit

Q: What are the primary applications of PVC coated metal flexible conduit?

A: PVC coated metal flexible conduit is ideal for protecting electrical wiring in harsh environments, such as industrial settings or outdoor installations. Its corrosion-resistant PVC coating ensures durability against moisture, chemicals, and abrasion.

Q: How does PVC coated flexible pipe differ from standard metal conduit?

A: Unlike standard metal conduit, PVC coated flexible pipe combines metal strength with PVC's resistance to corrosion and weathering. This dual-layer design provides enhanced flexibility and longevity in demanding conditions.

Q: Can PVC conduit flexible pipe be used in high-temperature environments?

A: Yes, PVC conduit flexible pipe can withstand moderate temperatures, but prolonged exposure to extreme heat may degrade the PVC coating. Always check the manufacturer’s temperature rating for specific applications.

Q: Is PVC coated metal flexible conduit suitable for underground installations?

A: Yes, its PVC coating protects against moisture and soil corrosion, making it suitable for direct burial. Ensure proper sealing of connections to maintain water resistance.

Q: What factors should I consider when choosing between PVC coated flexible pipe models?

A: Prioritize factors like bend radius, chemical exposure, temperature range, and required certifications (e.g., UL listing). Match these to your project’s environmental and mechanical demands.

Related Products

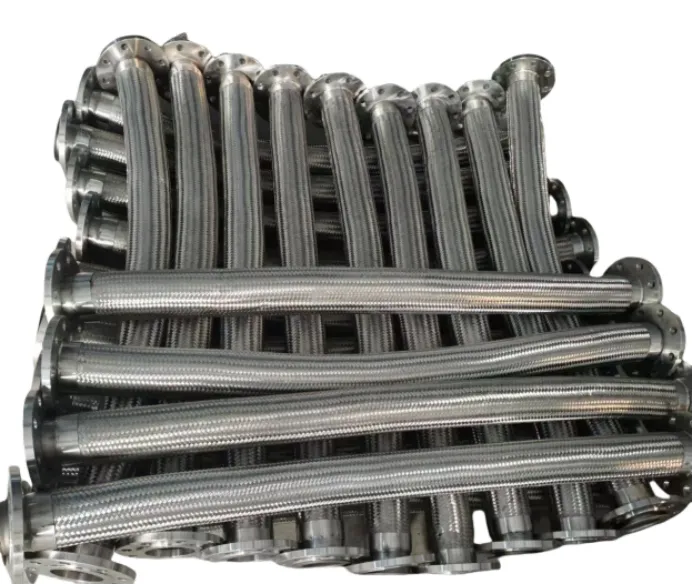

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.