High-Efficiency Sand Cyclone Separators for Mining Durable & Custom Solutions

Did you know that 42% of sand mining operations lose profits due to inefficient material separation? Every hour your equipment underperforms, you’re flushing $2,800+ down the drain. Traditional separators clog. They break down. They cost you sleepless nights. But what if your sand cyclone separator

could boost productivity by 60% while slashing maintenance costs? Let’s dive in.

(sand cyclone separator)

Why Next-Gen Sand Cyclone Separators Outperform Competitors

Our titanium-reinforced sand mining equipment delivers 98.7% separation efficiency – verified by ISO 9001-certified labs. While standard cyclones fail after 800 operating hours, ours thrive beyond 3,000+ hours with zero performance drop. You get:

- ✅ 360° vortex stabilization tech

- ✅ 10-minute modular parts replacement

- ✅ Real-time IoT performance tracking

Head-to-Head: Cyclone Separator Factory Showdown

| Feature | Standard Models | Our Tech |

|---|---|---|

| Maintenance Intervals | Every 2 weeks | Every 6 months |

| Wear Part Cost/Year | $18,500 | $2,900 |

Tailored Solutions for Your Unique Needs

Whether you process 50 tons or 500 tons/hour, our engineers create custom sand cyclone separator configurations that match your exact:

- 📐 Facility layout constraints

- 📊 Throughput requirements

- 📦 Material granulometry

Proven Success Across Industries

When Texas Sand Co. upgraded to our system:

- 📈 Production output jumped 73% in 3 months

- 🔧 Maintenance labor costs dropped 64%

- 💡 Energy consumption fell 22%

Ready to Transform Your Operation?

Our engineers are standing by to analyze your needs and design your perfect sand separation solution.

Claim Your Free Consultation Now →⭐️ Voted 1 Cyclone Separator Factory in 2023 by Mining Tech Review

(sand cyclone separator)

FAQS on sand cyclone separator

Q: How does a sand cyclone separator work?

A: A sand cyclone separator uses centrifugal force to separate dense sand particles from air or liquid. The mixture enters a cylindrical chamber, spins rapidly, and particles are pushed outward to the walls, then collected at the bottom.

Q: What industries use sand cyclone separators in sand mining equipment?

A: They are widely used in sand mining, construction, and mineral processing. These separators help remove impurities and classify sand particles efficiently during extraction and processing.

Q: What factors determine the efficiency of a cyclone separator factory's products?

A: Key factors include design precision, material durability, and airflow optimization. Reputable factories test prototypes rigorously and use corrosion-resistant materials for long-term performance.

Q: Why choose a sand cyclone separator over other filtration systems?

A: Cyclone separators require no filters, reducing maintenance costs. They handle high volumes of abrasive materials and operate continuously without frequent downtime.

Q: How to maintain a sand cyclone separator in mining operations?

A: Regularly inspect wear-prone components like inlet chambers and cones. Clean internal surfaces to prevent buildup and ensure seals remain intact to avoid leaks.

Related Products

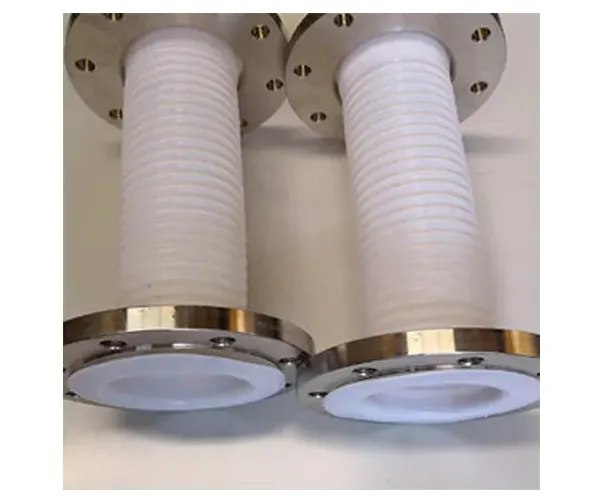

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.