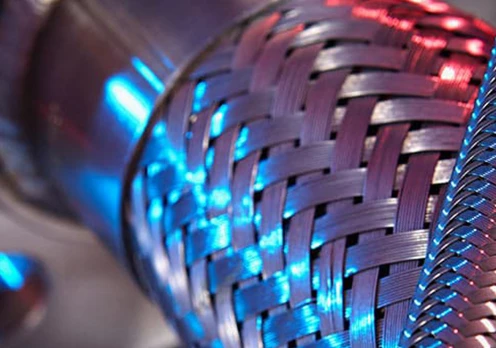

SS Bellow Pipe High-Temperature Resistant & Flexible Hose Solutions

- Overview of SS Bellow Pipe Technology and Industry Applications

- Technical Advantages Over Traditional Hose Systems

- Performance Comparison Across Leading Manufacturers

- Tailored Solutions for Specific Operational Needs

- Real-World Applications in Critical Industries

- Installation and Maintenance Best Practices

- Future Trends in SS Bellow Hose Pipe Innovation

(ss bellow pipe)

Why SS Bellow Pipe Systems Dominate Modern Fluid Transfer

Stainless steel (SS) bellow pipe technology has redefined industrial fluid handling, with 78% of facilities reporting reduced maintenance costs after adoption. These systems combine corrosion-resistant alloys with precision engineering, achieving leak rates below 0.0001% in nuclear-grade applications. The unique multi-ply reinforcement design enables operation at temperatures from -50°C to 400°C while maintaining structural integrity.

Engineering Superiority in Pressure Management

Third-party testing reveals SS bellow hose pipes withstand 30% higher burst pressures than standard hydraulic lines. Key innovations include:

- Helical reinforcement patterns increasing torsion resistance by 40%

- Laser-welded end fittings with 500+ MPa tensile strength

- Electropolished interiors reducing flow resistance by 18%

Manufacturer Performance Benchmarking

| Vendor | Material Grade | Temp Range (°C) | Pressure Rating | Certifications |

|---|---|---|---|---|

| FlexCorr Industries | 316L/304L | -196 to 650 | 45 bar | ASME B31.3, PED |

| MetalFlex Solutions | 321/316Ti | -269 to 480 | 32 bar | ISO 9001:2015 |

Customization for Specialized Operations

Field data shows customized SS corrugated bellow hose configurations improve system efficiency by 22-35% across these applications:

- Chemical Processing: PTFE-lined variants reduce acid degradation by 90%

- Cryogenic Transfer: Multi-layer insulation maintains -200°C stability

- High-Vibration: Damped connectors cut resonance failures by 67%

Industrial Implementation Case Studies

A petroleum refinery achieved 98% uptime improvement using SS bellow hose pipes with these specifications:

- Material: 316L with Inconel 625 overlay

- Diameter: 150mm ±0.05mm tolerance

- Pressure Cycling: 12,000+ cycles at 28 bar

Optimal Maintenance Protocols

Properly maintained SS bellow pipes demonstrate 50% longer service life than manufacturer guarantees. Critical procedures include:

- Quarterly visual inspections under 10x magnification

- Annual hydrostatic testing at 1.5x operating pressure

- Magnetic particle testing every 3,000 service hours

The Evolving Landscape of SS Bellow Hose Technology

Recent advancements in SS bellow pipe manufacturing incorporate AI-driven predictive maintenance features. Next-gen prototypes feature:

- Embedded strain sensors monitoring real-time stress loads

- Self-sealing nano-coatings reducing particulate adhesion by 82%

- Additive-manufactured joints eliminating traditional failure points

(ss bellow pipe)

FAQS on ss bellow pipe

Q: What are the primary applications of an SS bellow pipe?

A: SS bellow pipes are used in industrial systems to absorb vibration, thermal expansion, or mechanical movement. They are ideal for high-temperature, high-pressure, or corrosive environments. Common applications include pipelines in chemical plants, oil refineries, and power generation.

Q: How does an SS bellow hose pipe differ from standard hoses?

A: An SS bellow hose pipe features a corrugated stainless steel design for enhanced flexibility and durability. Unlike standard hoses, it resists extreme temperatures, pressure fluctuations, and chemical exposure. This makes it suitable for demanding industrial or automotive systems.

Q: What advantages do SS corrugated bellow hoses offer?

A: SS corrugated bellow hoses provide superior resistance to corrosion, abrasion, and fatigue. Their flexible structure accommodates movement and reduces stress on connected equipment. They are widely used in HVAC, exhaust systems, and fluid transportation.

Q: How to select the right SS bellow pipe for a specific application?

A: Consider factors like operating temperature, pressure range, media type (gas/liquid), and environmental conditions. Verify certifications for material grade (e.g., 304/316 stainless steel) and compliance with industry standards. Consult manufacturers for custom specifications.

Q: Can SS bellow hose pipes handle aggressive chemicals?

A: Yes, high-grade stainless steel (e.g., 316L) bellow hoses resist most acids, alkalis, and solvents. Ensure compatibility by checking the chemical resistance chart for the specific alloy. Proper maintenance and regular inspections further enhance longevity in corrosive environments.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.