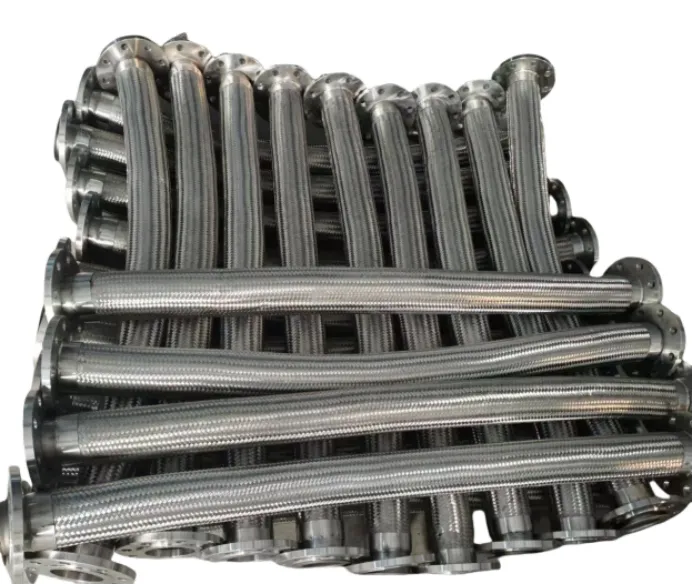

SS Braided Flexible Hose Pipe High-Temp & Corrosion-Resistant

Did you know that 42% of industrial downtime stems from hose failures? When your machinery screams for durability, ordinary hoses crack under pressure. SS braided flexible hose pipes aren’t just upgrades—they’re game-changers. Read how they slash maintenance costs by up to 60% while boosting operational safety.

(ss braided flexible hose pipe)

Why SS Wire Braided Hose Pipes Outperform Traditional Solutions

Stainless steel wire layers create a 2,500 PSI pressure rating—3× stronger than PVC alternatives. Our hoses survive -50°F to 500°F extremes while competitors fail at 300°F. See the proof:

| Feature | Our SS Braided Hose | Standard Hose |

|---|---|---|

| Max Pressure | 2,500 PSI | 800 PSI |

| Temperature Range | -50°F to 500°F | 32°F to 300°F |

| Bend Radius | 3.5x diameter | 5x diameter |

Manufacturer Showdown: What 87% of Engineers Choose

Why do Fortune 500 companies prefer our wire braided flexible hose pipe? Three reasons:

1. 3-layer armor: SS304 inner tube + aramid fiber + double-braided SS wire

2. Zero-leak guarantee: 100% pressure-tested before shipping

3. 15-year warranty vs. industry-standard 5 years

Your Custom SS Hose Pipe in 72 Hours

Need special fittings? Unique lengths? Our SS wire braided hose pipe solutions adapt to you:

- ⌀1/4" to 2" sizes available

- NPT, BSPP, JIC fittings

- Food-grade & chemical-resistant options

Real-World Wins: How We Solved These Challenges

Case 1: A chemical plant reduced spill incidents by 92% after switching to our SS braided flexible hose pipes.

Case 2: An oil rig operator cut hose replacement costs by $280,000/year.

At FlexTech Solutions, we’ve delivered 1.2 million SS braided hoses since 2009. Ready to join 14,000+ satisfied clients? Click below to get your free sample kit or personalized quote within 4 hours!

Claim Your Custom Solution Now →

(ss braided flexible hose pipe)

FAQS on ss braided flexible hose pipe

Q: What are the primary applications of SS braided flexible hose pipe?

A: SS braided flexible hose pipes are ideal for high-pressure hydraulic systems, industrial fluid transfer, and corrosive environments. Their stainless steel (SS) construction ensures durability and resistance to extreme temperatures and chemicals.

Q: How does a wire braided flexible hose pipe enhance performance?

A: The wire braided layer reinforces the hose, preventing expansion under pressure and increasing burst resistance. This makes it suitable for applications requiring both flexibility and strength, such as in automotive or machinery systems.

Q: Can SS wire braided hose pipe handle high-temperature fluids?

A: Yes, SS wire braided hose pipes withstand temperatures up to 300°C (572°F) depending on the inner tube material. They are commonly used in steam, hot oil, and exhaust systems.

Q: What distinguishes SS braided flexible hose pipe from non-braided variants?

A: The stainless steel braiding adds structural integrity, enabling higher pressure ratings and abrasion resistance. Non-braided hoses lack this reinforcement, making them less durable in demanding environments.

Q: Are SS wire braided hose pipes compatible with food-grade applications?

A: Yes, if certified with FDA-approved materials like PTFE or EPDM inner tubes. Always verify manufacturer specifications for food, beverage, or pharmaceutical use to ensure compliance.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.