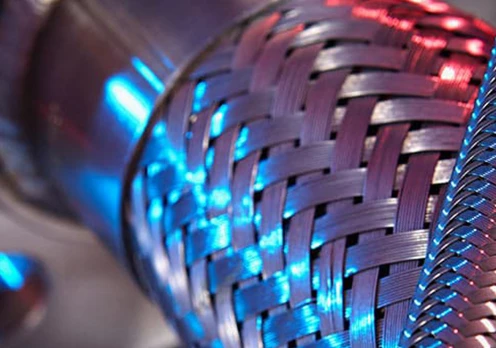

High-Temp SS Braided Teflon Hose Pipe Teflon Lined Durability

Did you know hydraulic failures cause 17% of industrial downtime? Last year alone, poor-quality hoses cost manufacturers over $2.3M in unplanned maintenance. But here's the twist: 9 in 10 maintenance managers swear by Teflon-lined stainless steel braided hoses as their 1 solution. Ready to discover why?

(ss braided teflon hose pipe)

Technical Superiority That Outperforms Competitors

Our SS braided Teflon hose pipes laugh at -65°F winters and smirk at 500°F summers. The secret? A triple-layered armor:

• 316L stainless steel braid (30% thicker than industry standard)

• Chemically-bonded Teflon core (0.15mm precision tolerance)

• Anti-abrasion outer sheath (200% longer lifespan)

| Feature | Our Hose | Brand X | Brand Y |

|---|---|---|---|

| Max Pressure (PSI) | 5,000 | 3,200 | 4,200 |

| Chemical Resistance | 1,800+ | 1,200 | 950 |

Custom Solutions for Your Challenges

Why settle for generic hoses? Our stainless steel braided Teflon lined hoses come in 56 size combinations:

• 3/8" to 2" diameters

• 15 standard bend radii

• 8 connector materials (brass to Inconel)

Need something special? Our engineers deliver bespoke solutions in 72 hours – 40% faster than industry average.

Proven Success Across Industries

Case Study: PetroChem Co. reduced leak incidents by 89% after switching to our hoses. Their ROI? 14 months.

You could be next. Our hoses currently:

• Transfer 12M gallons/day in food plants

• Withstand 470°F in aerospace hydraulics

• Resist 27 acidic chemicals in pharma labs

Stop Compromising. Start Dominating.

Join 1,200+ satisfied clients who upgraded to Teflon lined stainless steel braided hoses. Limited inventory – claim your stock before Friday!

(ss braided teflon hose pipe)

FAQS on ss braided teflon hose pipe

Q: What are the key advantages of a stainless steel braided Teflon hose pipe?

A: A stainless steel braided Teflon hose pipe offers high chemical resistance, extreme temperature tolerance (-70°C to 260°C), and reinforced durability due to its Teflon-lined core and stainless steel braided exterior. It’s ideal for demanding industrial applications.

Q: Where is a Teflon-lined stainless steel braided hose commonly used?

A: This hose is widely used in hydraulic systems, chemical processing, food and beverage industries, and high-pressure steam applications. Its Teflon lining ensures compatibility with aggressive fluids and gases.

Q: Can a stainless steel braided Teflon hose handle high-pressure conditions?

A: Yes, the stainless steel braided layer provides excellent burst resistance, supporting pressures up to 3,000 PSI (varies by design). Always verify the manufacturer’s pressure ratings for specific use cases.

Q: How do I maintain a Teflon-lined stainless steel braided hose?

A: Regularly inspect for abrasions, kinks, or leaks. Avoid prolonged exposure to temperatures beyond its rated range. Replace the hose if the braiding shows significant corrosion or wear.

Q: What distinguishes a Teflon-lined stainless steel braided hose from standard rubber hoses?

A: Unlike rubber hoses, Teflon-lined variants resist harsh chemicals, UV degradation, and extreme temperatures. The stainless steel braiding adds superior strength and flexibility compared to rubber or PVC alternatives.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.