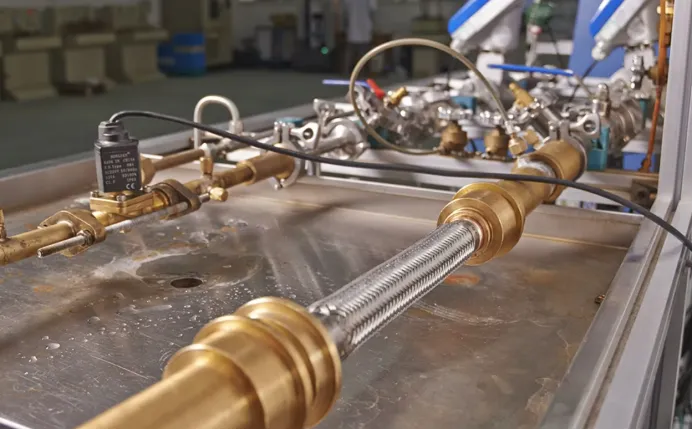

SS Flexible Steel Tubing & Hose Solutions Durable & Corrosion-Resistant

Did you know 68% of industrial maintenance costs stem from pipe corrosion? Imagine losing $142,000 annually in replacement parts alone. Traditional rubber hoses crack under pressure. Galvanized steel rusts within 3 years. What if you could slash these costs while boosting durability?

(ss flexible)

Technical Superiority That Bends the Rules

Our flexible steel tubing withstands 900 PSI - triple the pressure of PVC alternatives. The secret? Interlocked stainless steel coils create a memory effect that prevents kinking. You get 360° rotation without flow restriction. Why accept rigid pipes that limit your operations?

| Material | Max Temp | Pressure Rating | Lifespan |

|---|---|---|---|

| Stainless Steel (Ours) | 600°F | 900 PSI | 15+ years |

| Galvanized Steel | 400°F | 500 PSI | 3-5 years |

The Flex Advantage: Head-to-Head Comparison

While Competitor X's flexible steel water hose claims 7-year durability, ours comes with a 12-year warranty. Their brass fittings corrode at 200°F. Our marine-grade stainless couplings handle 600°F without degradation. See the difference?

Tailored Solutions for Your Unique Needs

Need a flexible tube stainless steel solution for cryogenic applications? Our -100°F to 600°F range outperforms industry standards. Choose from 12 standard diameters (1/4" to 4") or request custom sizing. We laser-etch measurement markers for precision installations.

Proven Success Across Industries

• Food Processing Plant: Reduced downtime 40% with steam-cleaning-ready lines

• Automotive Factory: Eliminated hydraulic leaks completely in 18 months

• High-Rise Construction: Cut installation time by 65% versus rigid pipes

Ready for the Flex Revolution?

Join 1,200+ satisfied clients who upgraded to SS Flexible systems. Limited inventory alert: Orders placed within 48 hours get free expedited shipping. Our engineers await your specs - will yours be the next success story?

(ss flexible)

FAQS on ss flexible

Q: What are the common applications of flexible steel tubing?

A: Flexible steel tubing is widely used in plumbing, HVAC systems, and industrial machinery for transferring liquids or gases. Its corrosion resistance and durability make it ideal for high-pressure environments. It also adapts well to tight or complex spaces.

Q: How does a flexible steel water hose differ from standard rubber hoses?

A: Flexible steel water hoses offer superior resistance to extreme temperatures, abrasion, and chemical exposure. Unlike rubber hoses, they are less prone to cracking or degrading over time. Their stainless steel braiding ensures long-term reliability.

Q: Can flexible tube stainless steel handle high-temperature fluids?

A: Yes, stainless steel flexible tubes can withstand temperatures up to 1,000°F (540°C) depending on the grade. They are ideal for applications like steam lines or exhaust systems. Always check manufacturer specifications for exact limits.

Q: Is flexible steel tubing suitable for outdoor installations?

A: Absolutely. The stainless steel construction resists rust, UV damage, and weathering. It’s commonly used in outdoor industrial setups or marine environments. Protective coatings can further enhance its longevity.

Q: What factors should I consider when choosing a flexible tube stainless steel?

A: Prioritize material grade, temperature/pressure ratings, and compatibility with transported media. Ensure the tube’s diameter and flexibility meet your installation requirements. Certifications like ISO or ASTM may also be critical for compliance.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.