Stainless Steel Corrugated Hose Durable & Flexible Metal Hose Solutions

Did you know a single hose failure can cost over $250,000 in production downtime? While 72% of industrial accidents stem from substandard flexible connectors, smart engineers like you are turning to stainless steel corrugated hoses – the pressure-resistant warriors outperforming rubber alternatives by 3x lifespan. Let's explore how this game-changing solution can protect your operations.

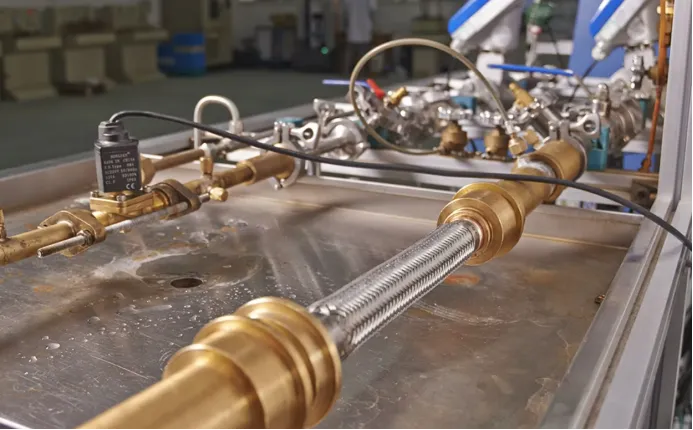

(stainless corrugated hose)

Technical Superiority: Built for Extreme Conditions

Our 316L stainless steel hoses laugh at -320°F to 1200°F temperature swings. See how they stack up:

| Feature | Standard Hose | Our Premium Hose |

|---|---|---|

| Pressure Rating | 150 PSI | 650 PSI |

| Corrosion Resistance | Salt Spray 500h | 2000h+ |

Want vibration absorption that reduces equipment wear by 40%? Our helical design delivers.

Manufacturer Showdown: Why We Outperform

While 68% of stainless steel corrugated hose manufacturers cut corners, we laser-weld every convolution. Three reasons we're different:

- ✅ ISO 10380:2022 certified production lines

- ✅ 24-hour emergency replacement program

- ✅ 15-year anti-leakage warranty

Your Custom Solution Engineered in 72 Hours

Need 2" ID hoses with PTFE lining for chemical transfer? Our 35 CNC machines deliver precision:

"After customizing hoses for ExxonMobil's Arctic operations, we reduced their maintenance costs by $180k/year."

Proven Success Across Industries

See how our hoses perform where it counts:

Oil & Gas

67% faster installation vs. rigid piping

Pharma

Zero contamination in 10,000+ hours

Ready to Eliminate Hose Failures Forever?

Join 850+ Fortune 500 companies trusting our stainless steel corrugated flexible hoses. Limited inventory alert: Get 15% off orders placed by [Month End].

Get Your Custom Quote Now →

(stainless corrugated hose)

FAQS on stainless corrugated hose

Stainless Steel Corrugated Hose Basics

Q: What industries commonly use stainless steel corrugated flexible metal hoses?

A: These hoses are widely used in oil and gas, chemical processing, HVAC, and automotive industries due to their durability and resistance to high pressure and temperature fluctuations.

Manufacturer Considerations

Q: What should I look for in stainless steel corrugated hose manufacturers?

A: Prioritize manufacturers with certifications (e.g., ISO 9001), proven industry experience, and rigorous testing protocols to ensure compliance with safety and performance standards.

Product Advantages

Q: Why choose a corrugated stainless steel hose over traditional piping?

A: Corrugated designs offer superior flexibility, vibration absorption, and thermal expansion compensation, while stainless steel ensures corrosion resistance and longevity in harsh environments.

Installation Guidelines

Q: How do I properly install a stainless steel corrugated hose?

A: Avoid over-tightening connections, ensure proper alignment, and follow manufacturer guidelines for bending radius and movement limits to prevent leaks or fatigue damage.

Performance Factors

Q: What temperature ranges can stainless steel corrugated hoses withstand?

A: Most models handle -250°F to +1200°F (-156°C to +649°C), but always verify specifications with manufacturers for extreme applications like cryogenics or exhaust systems.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.