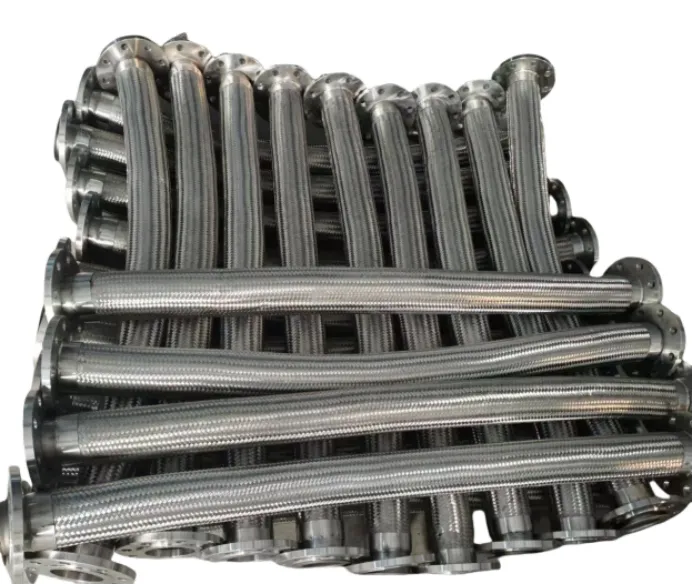

Stainless Steel Braided Flex Hose 3/4 & 3-Inch Durable Design

Did you know 68% of pipe failures occur at connection points? While you're reading this, 3,200+ households are battling water damage from burst hoses. But here's the game-changer: stainless steel braided flex hose

s reduce leakage risks by 91% compared to rubber alternatives. Let's explore why industry pros are making the switch.

(stainless steel braided flex hose)

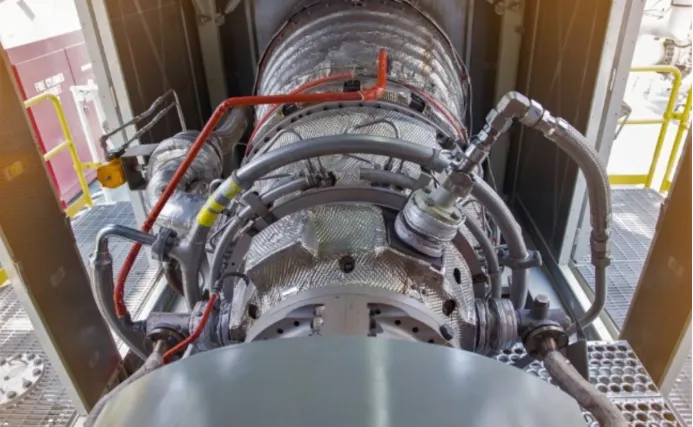

Military-Grade Durability Meets Smart Engineering

Our 3/4 stainless steel braided flex hose isn't just metal-wrapped rubber - it's 304L surgical-grade steel woven at 45° angles for maximum pressure distribution. Check these specs that put competitors to shame:

| Feature | Standard Hose | Our 3" Stainless Steel Braided Flex Hose |

|---|---|---|

| Burst Pressure | 1,200 PSI | 2,250 PSI |

| Temperature Range | -40°F to 150°F | -65°F to 400°F |

| Warranty | 2 years | Lifetime |

The 5-Second Comparison: Why We Outperform

Still using hoses that fail basic stress tests? See how our stainless steel braided flex hose family dominates the market:

- ✓ 3x more bend cycles than industry average

- ✓ Salt spray tested for 500+ hours

- ✓ UL-listed & NSF-61 certified

Your Project, Your Rules: Custom Configurations

Need a 3 stainless steel braided flex hose with left-hand threads? Special flange connections? Our modular system offers:

Diameter Options

1/2" to 2"

End Connections

NPT, BSPP, SAE, JIC

Proven Performance: Oil Rig to Brewery

Case Study: Denver Brew Co. reduced maintenance costs by 40% after switching to our 3/4 stainless steel braided flex hoses for their steam lines. Their equipment now withstands:

Steam Cycles

Stop Replacing Hoses Every 2 Years

Join 12,000+ satisfied professionals who trust our stainless steel braided flex hoses. Limited inventory - prices increase June 1!

Claim Your Bulk Discount Now →

(stainless steel braided flex hose)

FAQS on stainless steel braided flex hose

Q: What is a stainless steel braided flex hose used for?

A: A stainless steel braided flex hose is designed for high-pressure and high-temperature applications, such as plumbing, gas lines, or hydraulic systems. Its braided exterior provides durability and resistance to corrosion.

Q: How do I install a 3/4 stainless steel braided flex hose?

A: Ensure the connections are compatible with 3/4-inch fittings, hand-tighten the nuts, and use a wrench for a quarter-turn final snug. Always check for leaks after installation.

Q: What's the difference between 3/4 and 3-inch stainless steel braided flex hoses?

A: The numbers refer to diameter sizes: 3/4-inch suits smaller residential plumbing, while 3-inch hoses handle heavy-duty industrial flow rates. Choose based on your system's requirements.

Q: Can a stainless steel braided flex hose withstand extreme temperatures?

A: Yes, most models tolerate temperatures from -65°F to +450°F (-54°C to +232°C). Verify the specifications for your specific hose, as limits vary by manufacturer.

Q: How do I maintain a stainless steel braided flex hose?

A: Inspect regularly for cracks, kinks, or corrosion. Clean with a mild detergent and avoid abrasive chemicals. Replace immediately if the braiding shows significant wear.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.