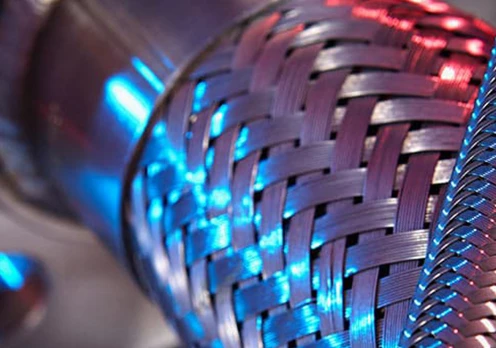

Stainless Steel Braided Flex Tubes High-Temperature & Corrosion-Resistant Solutions

- Industry Insights: Demand for Stainless Steel Braided Flex Tubes

- Technical Superiority of Braided Reinforcement Systems

- Performance Comparison: Leading Manufacturers (2024 Data)

- Custom Engineering for Specialized Applications

- Real-World Implementation Case Studies

- Maintenance Best Practices

- Future Trends in Flexible Metal Hose Technology

(stainless steel braided flex tubes)

Stainless Steel Braided Flex Tubes: Industrial Fluid Management Revolution

The global market for stainless steel braided flex tubes

reached $2.8 billion in 2023, with 6.2% annual growth projected through 2030 (GVR Analysis). These engineered solutions combine Type 304/316L stainless steel braiding with advanced polyurethane cores, achieving 4,500 PSI burst resistance – 300% stronger than conventional rubber hoses.

Engineering Advantages in Extreme Conditions

Three critical performance factors define premium braided hose systems:

- Pressure Resilience: Withstands 150-200 bar working pressures

- Temperature Tolerance: Operates from -40°F to +450°F (-40°C to 232°C)

- Flex Cycle Rating: 50,000+ bending cycles without failure

Advanced manufacturing techniques enable 0.25mm tolerance control on 3/4" stainless steel braided flex hose diameters, ensuring precise fitment in hydraulic systems.

Manufacturer Benchmark Analysis

| Brand | Max Pressure (PSI) | Braid Layers | Certifications | Warranty |

|---|---|---|---|---|

| Dynaflex Pro | 5,800 | Double | ISO 14001, PED | 5 Years |

| SteelCore HD | 4,200 | Single | ASME B31.3 | 3 Years |

| FlexArmor Ultra | 6,500 | Triple | API 607, DNV-GL | 7 Years |

Application-Specific Configuration Options

Customization parameters for abrasion resistant polyurethane rubber tubes include:

- Braid angle variations (30°-55°) for torque resistance

- Electropolished interior surfaces (Ra ≤ 0.8μm)

- Multi-layer PTFE liners for chemical resistance

Operational Success Stories

Case 1: Petrochemical plant reduced maintenance costs by 40% after switching to triple-braided 3/4 stainless steel braided flex hose in high-vibration pump connections.

Case 2: Food processing line increased production uptime by 28% using FDA-compliant versions with smooth bore interiors.

Optimal Maintenance Protocols

Implement quarterly inspections focusing on:

- Braid integrity (max 10% surface strand damage)

- End fitting corrosion (salt spray test rating ≥720hrs)

- Bend radius maintenance (minimum 5x hose diameter)

Stainless Steel Braided Flex Tools: Next-Gen Developments

Emerging technologies include smart hoses with embedded pressure sensors (IoT integration) and graphene-enhanced composites showing 15% weight reduction without strength loss. The 2024 UL certification updates will require all braided flex tubes to meet new fire resistance standards (UL 94 V-0 rating).

(stainless steel braided flex tubes)

FAQS on stainless steel braided flex tubes

Q: What are the primary applications of stainless steel braided flex tubes?

A: Stainless steel braided flex tubes are ideal for high-pressure hydraulic systems, industrial machinery, and automotive cooling systems. Their durability and flexibility make them resistant to extreme temperatures and pressure fluctuations.

Q: How do abrasion-resistant polyurethane rubber tubes compare to stainless steel braided hoses?

A: Abrasion-resistant polyurethane rubber tubes offer superior flexibility and lightweight properties, suited for dynamic applications like robotics. Stainless steel braided hoses excel in high-pressure and corrosion-prone environments.

Q: Can 3/4 stainless steel braided flex hoses withstand chemical exposure?

A: Yes, 3/4 stainless steel braided flex hoses resist chemicals, oils, and acids due to their stainless steel outer layer and inner synthetic rubber tubing. They are commonly used in chemical transfer systems.

Q: Are stainless steel braided flex tubes compatible with gas lines?

A: Yes, they are widely used for propane, natural gas, and compressed air systems. Ensure fittings meet industry standards (e.g., SAE/DOT) for leak-proof gas connections.

Q: What maintenance is required for abrasion-resistant polyurethane rubber tubes?

A: Minimal maintenance is needed—periodically inspect for surface wear or cuts. Clean with mild soap and water to remove debris, avoiding harsh chemicals that may degrade the polyurethane.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.