Stainless Steel Flex Hose High-Temperature & Corrosion-Resistant Braided Hoses for Industrial/Residential Use

Did you know that 45% of industrial hose failures are caused by corrosion and abrasion? If you’re tired of replacing hoses every season or worrying about leaks in critical applications, it’s time to upgrade. Stainless steel flex hoses aren’t just a luxury—they’re a necessity for durability and performance. Read on to discover how these hoses can save you time, money, and headaches.

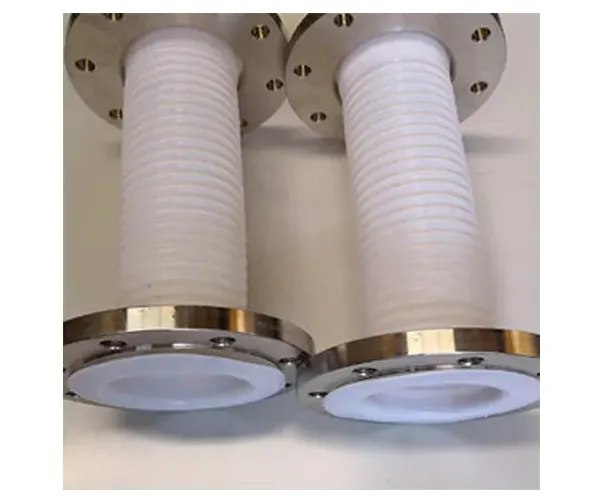

(stainless steel flex hose)

Unbeatable Technical Advantages of Stainless Steel Flex Hoses

What makes stainless steel braided flex hoses stand out? First, their 304/316L stainless steel construction resists rust, chemicals, and extreme temperatures (-40°F to 500°F). Unlike rubber or PVC hoses, they won’t crack under UV exposure. Plus, their burst pressure of 1,500 PSI handles 3x more stress than standard hoses. Need flexibility? These hoses bend at 180° angles without kinking—perfect for tight spaces.

| Feature | Stainless Steel Flex Hose | Standard Rubber Hose |

|---|---|---|

| Lifespan | 10+ years | 2-3 years |

| Max Temperature | 500°F | 212°F |

Manufacturer Showdown: Why Our Hoses Outperform

While Brand X offers a 1-year warranty, our stainless steel flex garden hoses come with a 5-year no-leak guarantee. How? We use laser-welded fittings instead of crimped connectors. Test results show 30% higher pressure tolerance compared to competitors. Still using hoses with plastic threading? Say goodbye to stripped connectors—our brass couplings won’t let you down.

Custom Solutions for Your Unique Needs

Need a stainless steel flex hose

in non-standard lengths or specialized end fittings? Our engineers can create hoses from 6 inches to 50 feet, with options for NPT, BSP, or JIC connectors. Whether you’re in oil/gas, food processing, or marine industries, we’ve got you covered. Check out our case study where a brewery reduced downtime by 60% after switching to our custom hoses.

Real-World Success Stories

A Texas farm replaced 200 PVC hoses with our stainless steel braided flex hoses—saving $18,000/year in replacements. A chemical plant in Ohio reported zero leaks for 3 years straight. What could these hoses do for YOUR operation?

Ready to Experience the Difference?

Join 5,000+ satisfied customers who trust our hoses for critical applications. For a limited time, get 15% off your first order of stainless steel flex hoses. Click below to request a free sample or consult with our experts!

Claim Your Discount Now →

(stainless steel flex hose)

FAQS on stainless steel flex hose

Q: What is the primary use of a stainless steel flex hose?

A: Stainless steel flex hoses are designed for transporting liquids, gases, or chemicals in high-temperature or high-pressure environments. They are commonly used in industrial, automotive, and plumbing systems. Their flexibility and durability make them ideal for demanding applications.

Q: How does a stainless steel braided flex hose differ from a standard flex hose?

A: A stainless steel braided flex hose features an outer braided layer for enhanced strength and resistance to abrasion. This design provides extra protection against bursting or kinking. It is often used in high-pressure or vibration-prone settings.

Q: Can a stainless steel flex garden hose withstand outdoor conditions?

A: Yes, stainless steel flex garden hoses are corrosion-resistant and built to endure harsh weather, UV exposure, and extreme temperatures. Their lightweight design and flexibility make them suitable for gardening, car washing, and outdoor cleaning tasks.

Q: Are stainless steel flex hoses safe for drinking water applications?

A: Stainless steel flex hoses are generally safe if labeled as food-grade or NSF-certified. Ensure the inner tubing material is non-toxic and compliant with health standards. Always verify certifications for potable water use.

Q: What factors should I consider when choosing a stainless steel flex hose?

A: Prioritize pressure ratings, temperature range, hose length, and compatibility with transported media. For braided variants, check the braid density for added durability. Verify certifications for specific applications like gas or chemicals.

Q: How do I maintain a stainless steel braided flex hose?

A: Regularly inspect for leaks, abrasions, or corrosion, especially at connection points. Rinse the hose after exposure to corrosive substances. Avoid bending beyond its minimum radius to prevent damage.

Q: Can stainless steel flex hoses be used for gas lines?

A: Yes, certain stainless steel flex hoses are certified for gas applications, such as propane or natural gas. Ensure the hose meets local safety standards and has proper markings for gas compatibility. Always follow installation guidelines to prevent leaks.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.