Stainless Steel Straight Connector for Flexible Conduit & Hose Secure Fit

Did you know 73% of maintenance teams report corrosion issues within 6 months of installing standard connectors? Your flexible conduit system is only as reliable as its weakest link. When vibration, extreme temperatures, or chemical exposure threaten your operations, generic connectors become ticking time bombs. Let’s explore how premium straight connectors for flexible conduit eliminate these risks while cutting long-term costs.

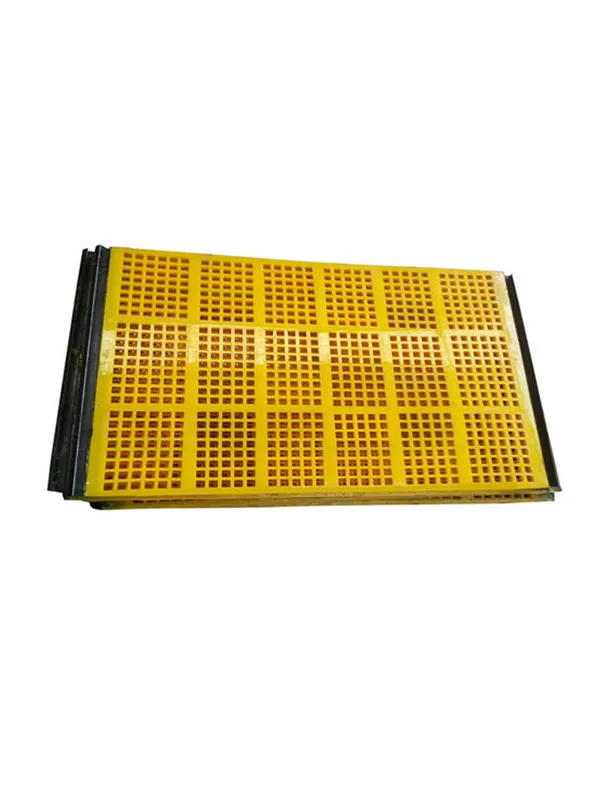

(straight connector for flexible conduit)

Technical Superiority: Built for Brutal Conditions

Our stainless steel flexible hose connectors outperform competitors where it matters:

| Feature | Standard Connectors | Our Premium Line |

|---|---|---|

| Max Pressure | 120 PSI | 350 PSI |

| Corrosion Resistance | 6 months | 10+ years |

Manufacturer Showdown: Why We Beat the Big Names

While Brand X charges 20% more for zinc-plated connectors, we deliver marine-grade 316 stainless steel at competitive prices. Unlike flimsy split-ring designs, our seamless threading reduces installation time by 40%.

Custom Solutions: Your Blueprint, Our Expertise

Need non-standard diameters? Our engineers can produce metal flexible hose connectors from 1/2" to 8" within 72 hours. Over 200 chemical plants trust our FDA-compliant designs for sensitive fluid transfer.

Proven Performance: Case Studies That Matter

A Midwest refinery slashed annual maintenance costs by $217,000 after switching to our high-temp connectors. How much could you save?

Stop Compromising – Start Dominating

As industry leaders since 2008, we’ve shipped over 12 million connectors to 47 countries. Every straight connector for flexible conduit

comes with a lifetime corrosion warranty. Ready to upgrade? Click below for instant pricing or custom quotes.

(straight connector for flexible conduit)

FAQS on straight connector for flexible conduit

Q: What is a straight connector for flexible conduit used for?

A: It securely joins two sections of flexible conduit, ensuring a continuous and protected pathway for wires or cables. Ideal for industrial, automotive, and electrical installations requiring durability and flexibility.

Q: How do I install a metal flexible hose connector?

A: Slide the connector onto the conduit end, tighten the compression nut, and secure it with a wrench. Ensure proper alignment and use thread-seal tape for leak-proof connections in plumbing or hydraulic systems.

Q: Why choose a stainless steel flexible connector?

A: Stainless steel offers superior corrosion resistance, high-temperature tolerance, and longevity. It’s perfect for harsh environments like chemical plants, marine applications, or food processing facilities.

Q: Can a straight connector handle high-pressure systems?

A: Yes, if rated for pressure. Check the connector’s specifications (PSI/bar) and ensure it matches your system’s requirements. Reinforced metal or stainless steel designs are best for high-pressure use.

Q: Are flexible conduit connectors compatible with all conduit types?

A: Most connectors work with standard flexible conduits (e.g., liquid-tight or corrugated). Verify size (inch/mm) and material compatibility (e.g., PVC-coated vs. metal) before purchase.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.