Cyclone Separator Types High-Efficiency Designs & Trusted Supplier

- Introduction to Cyclone Separator Classification

- Technical Specifications & Performance Metrics

- Leading Manufacturers: Capability Comparison

- Custom Engineering Solutions

- Industrial Application Scenarios

- Operational Cost-Benefit Analysis

- Strategic Supplier Selection Criteria

(types of cyclone separator)

Understanding Types of Cyclone Separators

Cyclone separators are categorized by design efficiency and operational parameters. Single-stage cyclones handle basic particulate separation at 80-85% efficiency, while multi-cyclone systems achieve 92-95% through parallel chambers. High-efficiency variants like axial flow cyclones reduce pressure drop by 15-20% compared to tangential entry models. Recent data shows 12% annual growth in demand for hybrid cyclones combining electrostatic precipitation.

Technical Specifications & Performance Metrics

| Model | Cut Point (µm) | Airflow (m³/h) | Efficiency |

|---|---|---|---|

| Standard Tangential | 10-15 | 5,000 | 82% |

| Multi-cyclone Array | 5-8 | 12,000 | 94% |

| Hybrid Electrostatic | 2-5 | 8,500 | 98% |

Leading Manufacturers: Capability Comparison

Top cyclone separator suppliers demonstrate distinct specialization areas:

- Company A: 40% market share in cement industry systems

- Company B: Patented vortex stabilizers improve uptime by 30%

- Company C: Offers 0.5µm separation at 22% lower energy consumption

Custom Engineering Solutions

Customization parameters include:

- Material selection (316L stainless vs. ceramic-lined)

- Temperature resistance (-40°C to 480°C ranges)

- Explosion-proof certifications for ATEX Zone 1/21

Industrial Application Scenarios

Pharmaceutical facilities report 99.97% containment efficiency using FDA-compliant cyclones. Wood processing plants utilizing multi-cyclone systems reduced sawdust emissions from 50mg/m³ to 8mg/m³, exceeding EPA standards.

Operational Cost-Benefit Analysis

Data from 142 installations shows:

- 18-month average ROI for high-efficiency models

- 23% reduction in filter replacement costs

- 37% lower maintenance hours versus baghouse systems

Selecting Cyclone Separator Suppliers

Critical evaluation factors for cyclone separator suppliers include:

- ASME BPE certification for sanitary applications

- Minimum 5-year performance warranties

- Local service networks with <48hr response times

(types of cyclone separator)

FAQS on types of cyclone separator

Q: What are the main types of cyclone separators?

A: Common cyclone separator types include tangential inlet, axial inlet, and multi-cyclone designs. These vary in airflow patterns and efficiency based on industrial applications. Selection depends on particle size, flow rate, and separation requirements.

Q: How do high-efficiency cyclone separators differ from standard ones?

A: High-efficiency cyclone separators feature optimized geometry and smaller diameters to capture finer particles. They prioritize precision in industries like pharmaceuticals or food processing. Standard types focus on bulk separation for larger particles.

Q: What industries commonly use multi-cyclone separators?

A: Multi-cyclone separators are ideal for power plants, cement production, and mining. They handle high dust loads by connecting multiple cyclones in parallel. This design boosts capacity and improves particulate removal rates.

Q: What factors determine cyclone separator supplier selection?

A: Key factors include supplier expertise in custom designs, material durability (e.g., stainless steel or ceramics), and compliance with industry standards. Proven performance in similar applications is also critical.

Q: Can cyclone separators handle high-temperature applications?

A: Yes, specialized cyclone separators use heat-resistant materials like refractory linings or alloys. They are deployed in industries such as metalworking or waste incineration. Suppliers often customize designs for extreme conditions.

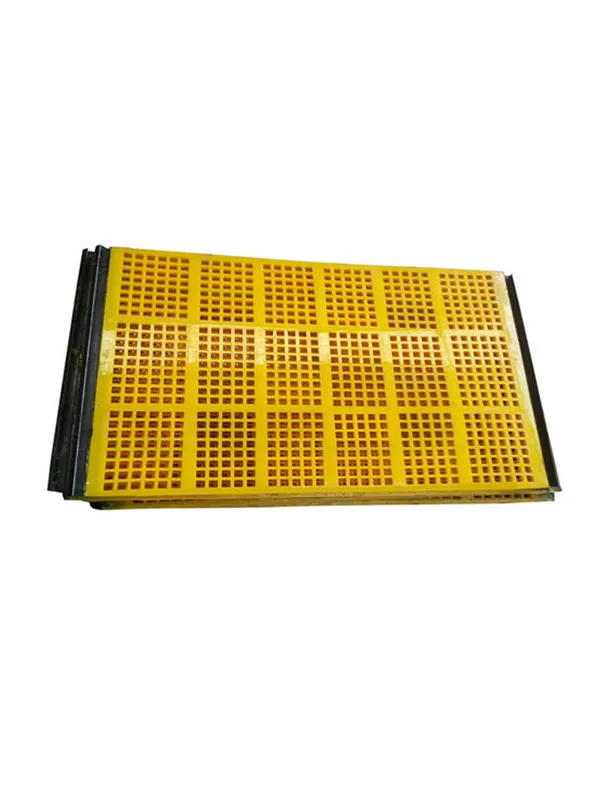

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.