Types of Mineral Processing Crushers, Screens & Efficient Solutions

Did you know 12-15% of mineral value gets lost through inefficient processing? Every year, mines waste $47 billion globally by using outdated equipment. Your operation deserves better. Discover how choosing the right types of mineral processing

systems can boost yields up to 23% while slashing maintenance costs.

(types of mineral processing)

Crushing Dominance: 4 Types of Crushers That Redefine Efficiency

When raw ore enters your plant, jaw crushers deliver 300-1,500 TPH primary reduction. But wait – are you using the optimal secondary crusher? Cone crushers handle abrasive materials 40% better than impact types. See our comparison table:

| Crusher Type | Throughput (TPH) | Power Consumption |

|---|---|---|

| Jaw Crusher | 300-1,500 | 150-250 kW |

| Cone Crusher | 150-800 | 200-400 kW |

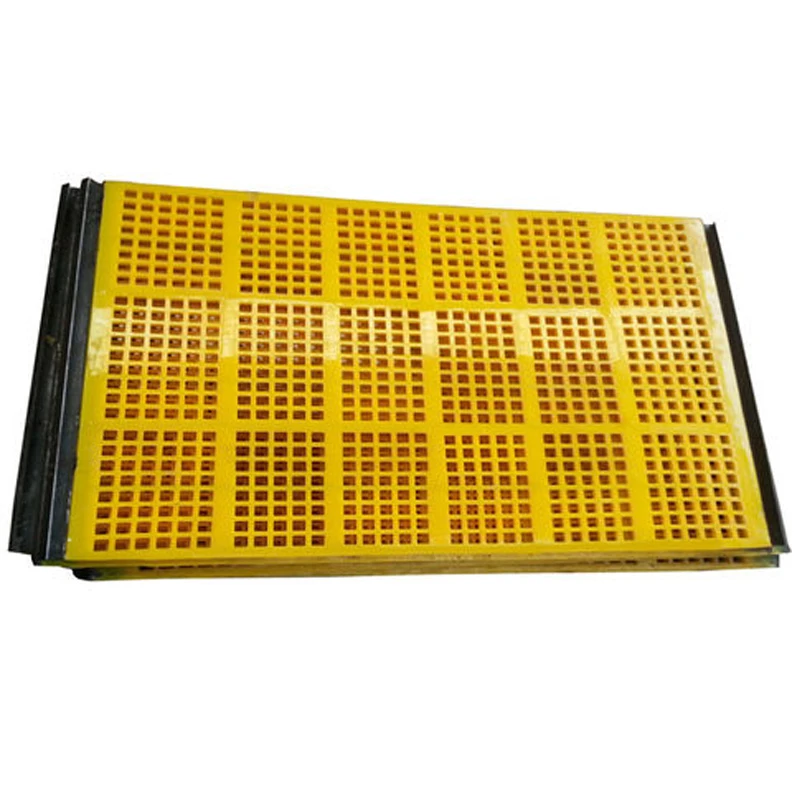

Screening Mastery: 3 Game-Changing Screen Types You Need Now

Vibrating screens process 2,000 TPH in coal plants, but high-frequency screens boost efficiency by 28% in metallic ores. Why settle for basic wedge wire when polyurethane panels last 3x longer? Our modular designs cut installation time by 65%.

Proven Results: Copper Mine Increases Recovery by 19%

Arizona-based operator upgraded to our tertiary cone crushers and banana screens. Result: 23% higher throughput and $4.2M annual savings. "The ROI came in 5 months flat," reports their plant manager.

Ready to Transform Your Mineral Processing?

Claim your FREE plant efficiency audit this month and get 3D process simulations worth $15,000!

(types of mineral processing)

FAQS on types of mineral processing

-

Q: What are the main types of mineral processing methods?

A: The primary types include physical processing (e.g., crushing, screening), chemical processing (e.g., leaching, flotation), and biological processing (e.g., bioleaching). These methods separate valuable minerals from ore based on their properties.

-

Q: What types of crushers are commonly used in mineral processing?

A: Common crushers include jaw crushers (for coarse crushing), gyratory crushers (for high-capacity operations), and cone crushers (for finer crushing). Each type is suited to specific ore characteristics and processing stages.

-

Q: How do screens function in mineral processing, and what types are used?

A: Screens separate particles by size using vibrating screens (for high efficiency), trommel screens (for wet or sticky materials), and scalping screens (to remove oversized material). They ensure proper classification and downstream process efficiency.

-

Q: What distinguishes different types of crushers in mineral processing?

A: Crushers differ by mechanism: jaw crushers compress material between fixed and moving plates, impact crushers use rapid collisions, and roll crushers apply pressure via rotating cylinders. Selection depends on hardness, size, and throughput needs.

-

Q: Why are multiple types of screens necessary in mineral processing?

A: Different screens address varying particle sizes and material conditions. For example, vibrating screens handle dry materials, while dewatering screens remove moisture. Proper screening optimizes recovery and reduces energy waste in later stages.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.