Durable Urethane Lined Pipes Corrosion-Resistant & Long-Lasting

Did you know pipeline corrosion costs manufacturers $276 billion annually? Imagine your production line halting because of cracked pipes. Picture chemical leaks creating safety hazards. Now breathe easy – urethane lined pipes

slash maintenance costs by 60% while doubling service life. Keep reading to discover how this game-changing technology solves your worst flow system nightmares.

(urethane lined pipes)

Technical Superiority: Urethane vs Traditional Materials

Why settle for steel pipes that rust or PVC that cracks under pressure? Our urethane lined pipe solutions deliver:

- ✅ 4x abrasion resistance vs carbon steel (ASTM G65 test data)

- ✅ Chemical resistance to pH 1-14 substances

- ✅ Operational range: -40°F to 250°F (-40°C to 121°C)

Manufacturer Showdown: What Top 3 Suppliers Miss

| Feature | Standard Supplier | Our Solution |

|---|---|---|

| Liner Thickness | 1/8" | 3/16" |

| Pressure Rating | 150 PSI | 300 PSI |

Tailored Solutions: Your System, Your Rules

Need lining pipes with polyurethane for odd angles? Special flange connections? Our engineers deliver:

- 🔧 Custom bend radii (1D to 5D)

- 🔧 Explosion-bonded liners

- 🔧 Rapid 72-hour turnaround

Proven Performance: Mining Giant Case Study

When a Nevada copper mine replaced their steel slurry lines with our urethane lined pipes:

📈 89% reduction in unplanned downtime

📈 14-month ROI achieved in 9 months

📈 3-year warranty coverage

Stop Losing Money to Pipe Failures

Join 850+ satisfied clients who boosted productivity with urethane lined piping systems. Limited 2024 installation slots available!

(urethane lined pipes)

FAQS on urethane lined pipes

Q: What are the benefits of urethane lined pipes?

A: Urethane lined pipes offer superior abrasion resistance, extended lifespan, and reduced maintenance costs. The polyurethane lining protects against corrosive substances and harsh environments.Q: In which industries are urethane lined pipes commonly used?

A: They are widely used in mining, chemical processing, and slurry transport industries. Their durability makes them ideal for handling abrasive and corrosive materials.Q: How does lining pipes with polyurethane improve performance?

A: Polyurethane lining minimizes friction and wear, enhancing flow efficiency. It also prevents material buildup and resists chemical degradation.Q: Can urethane lined pipes withstand high-pressure applications?

A: Yes, urethane linings maintain structural integrity under high pressure. They are engineered to handle demanding operational conditions without cracking or peeling.Q: How does urethane compare to rubber for pipe lining?

A: Urethane outperforms rubber in abrasion resistance and longevity. It also provides better flexibility and resistance to oils and solvents compared to traditional rubber linings.Related Products

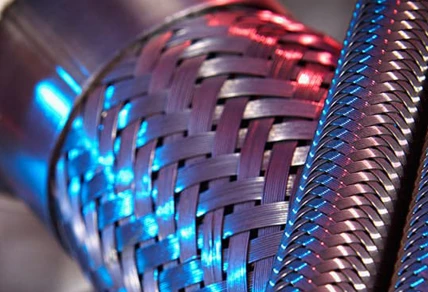

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.