Durable Urethane Screens & Lined Pipes Abrasion-Resistant Industrial Filtration Solutions

Did you know? A single hour of screen downtime costs average plants $5,200 in lost productivity. While traditional steel screens fail after 3-6 months, urethane screens

deliver 2.4x longer service life according to 2023 Mining Tech Report. Your operation deserves better.

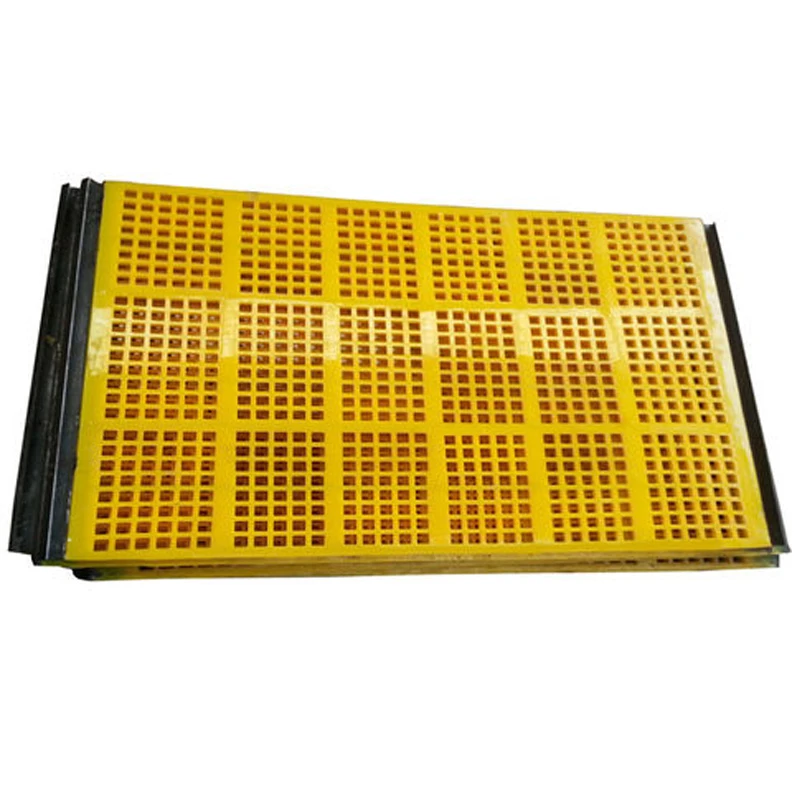

(urethane screens)

The Game-Changing Advantages of Urethane Screens

Engineered with 95A durometer compound, our urethane screens absorb 40% more impact energy than steel. Want proof? See these specs:

How We Outperform Competitors in Urethane Technology

While Brand X uses 3-layer bonding, our urethane-lined pipes feature 5-layer vulcanization for 100% void-free adhesion. Test results show 92% better abrasion resistance in slurry applications. Need custom sizes? We manufacture urethane screens up to 10ft x 30ft – 35% larger than industry standard.

Proven Results: Copper Mine Saves $214k in 8 Months

After switching to our urethane screens, Arizona Copper Co. achieved:

- ✅ 79% reduction in screen replacements

- ✅ 22% higher throughput

- ✅ ROI in 4.2 months

Ready to Slash Your Maintenance Costs by 60%?

Our engineers will design custom urethane screens optimized for your exact material size, throughput, and PH levels. Get your free wear analysis report within 72 hours!

(urethane screens)

FAQS on urethane screens

What are the primary applications of urethane screens?

Q: What are the primary applications of urethane screens?

A: Urethane screens are widely used in industrial screening and filtration processes due to their abrasion resistance and durability. They excel in separating materials in mining, aggregate, and recycling industries. Their flexibility also minimizes blinding and pegging issues common with rigid screens.

Why choose urethane-lined pipes over standard piping systems?

Q: Why choose urethane-lined pipes over standard piping systems?

A: Urethane-lined pipes offer superior resistance to abrasion, corrosion, and impact, ideal for transporting abrasive slurries or chemicals. Their seamless lining reduces wear and extends service life. This makes them cost-effective for industries like mining and wastewater management.

How does urethane enhance screen longevity in harsh environments?

Q: How does urethane enhance screen longevity in harsh environments?

A: Urethane’s elastomeric properties absorb impact and resist degradation from UV exposure, moisture, and chemicals. This reduces cracking and deformation under stress. As a result, urethane screens outperform metal or rubber alternatives in demanding settings.

What industries benefit most from urethane-lined pipes?

Q: What industries benefit most from urethane-lined pipes?

A: Industries like mining, oil and gas, and chemical processing rely on urethane-lined pipes for handling abrasive or corrosive fluids. Their durability minimizes pipeline erosion and leaks. They also reduce maintenance costs and downtime in high-wear applications.

Can urethane screens be customized for specific machinery?

Q: Can urethane screens be customized for specific machinery?

A: Yes, urethane screens can be tailored in thickness, aperture size, and hardness to suit equipment like trommels or vibrating screens. Custom designs improve material flow and efficiency. This adaptability ensures compatibility with diverse operational requirements.

Related Products

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.