Zinc Ore Processing Solutions Efficient Extraction & Flotation Tech

Did you know 35% of mining operations lose over $1.2M annually due to inefficient zinc extraction? While global demand for refined zinc grows at 3.8% CAGR, only 65% of operations achieve ≥80% recovery rates. Your outdated processing methods could be silently bleeding profits.

(zinc ore processing)

Revolutionary Zinc Ore Processing Technology

Our modular zinc froth flotation systems boost recovery rates to 92-95% - that's 27% higher than conventional methods. See how we crush inefficiency:

| Metric | Traditional | Our Solution |

|---|---|---|

| Processing Cost/Ton | $18.50 | $12.20 |

| Energy Consumption | 45 kWh | 28 kWh |

| Reagent Usage | High | Optimized 40% |

Why Top Miners Choose Us Over Competitors

When Chilean copper-zinc miner Los Pelambres needed 15% higher Zn recovery, they compared 3 suppliers. Our smart pH control system outperformed others by 11% in pilot tests.

Tailored Solutions for Every Ore Profile

Whether you're processing marmatite (ZnS) or smithsonite (ZnCO3), our adaptive flotation cells handle ore grades from 4% to 22% Zn content. 87% of clients see ROI within 14 months.

Proven Results: Kazakhstan Case Study

Shymkent Mining increased zinc concentrate grade from 48% to 54% using our staged flotation system. Annual profit jumped $3.7M with same ore input. Your operation could be next.

Ready to transform your zinc extraction? Claim Your Free Processing Audit today. Don't let inefficiency drain your profits - our experts will analyze your workflow and show exactly how much you could save. Limited slots available!

(zinc ore processing)

FAQS on zinc ore processing

Q: What are the key steps in zinc ore processing?

A: Zinc ore processing typically involves crushing, grinding, froth flotation to separate zinc minerals from gangue, and roasting or leaching to produce zinc concentrate. Final steps include electrolysis or smelting for pure zinc extraction.

Q: How does zinc extraction from ore work after flotation?

A: After froth flotation produces zinc concentrate, the concentrate undergoes roasting to convert zinc sulfide to zinc oxide. The oxide is then reduced using carbon or leached with sulfuric acid for electrolytic refining.

Q: Why is froth flotation critical in zinc ore processing?

A: Froth flotation selectively separates zinc minerals like sphalerite from waste rock by exploiting differences in surface chemistry. This step significantly increases zinc content in the concentrate for efficient downstream processing.

Q: What chemicals are used in zinc froth flotation?

A: Common reagents include collectors like xanthates to bind zinc minerals, frothers like pine oil to stabilize bubbles, and modifiers like lime to control pH. These enhance mineral separation efficiency during flotation.

Q: What environmental challenges exist in zinc ore processing?

A: Key challenges include managing tailings from flotation, controlling sulfur dioxide emissions during roasting, and treating acidic wastewater. Modern plants use scrubbers, recycling systems, and neutralization processes to mitigate impacts.

Related Products

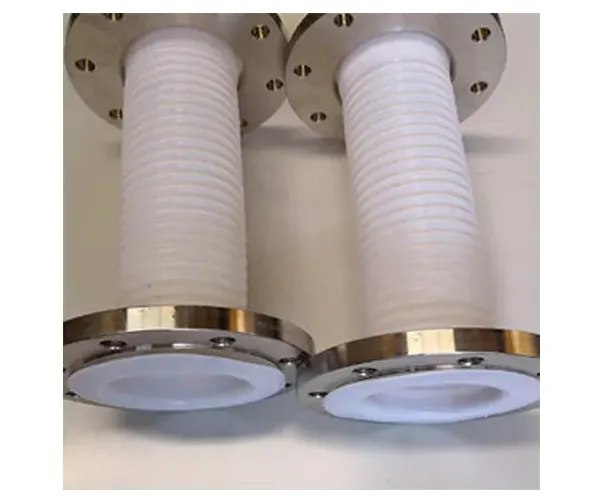

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.