Zinc Extraction from Ore High-Efficiency Froth Flotation & Processing Solutions

Did you know 30% of zinc ore value gets wasted through outdated extraction methods? With global zinc demand hitting 14 million metric tons in 2023 (ILZSG), mines using 20th-century tech struggle with 75% average recovery rates and spiraling energy costs. Here's how next-gen froth flotation turns crushed rock into profit magnets.

(zinc extraction from ore)

Why Our Zinc Froth Flotation Tech Outperforms Competitors

While competitors use static air flow systems, our AI-driven microbubble generators adapt to ore composition in real time. See the results:

| Metric | Traditional Systems | Our Solution |

|---|---|---|

| Recovery Rate | 75-82% | 89-92% |

| Energy Cost/Ton | $18.50 | $12.80 |

Tailored Zinc Extraction Systems for Your Ore Type

Whether you process sulfide ores or oxidized deposits, our modular systems deliver:

- ✓ 15% finer particle sizing

- ✓ pH control within ±0.3

- ✓ 24/7 remote monitoring

Case Study: 25% Output Boost at Peruvian Mine

After installing our ZF-9000 flotation cells, Cerro Verde Mine achieved:

🔥 91.4% zinc recovery from complex polymetallic ore

⚡ 18% lower reagent consumption vs. previous system

💰 ROI in 14 months through increased concentrate grades

Ready to Transform Your Zinc Recovery Rates?

Join 37+ mining operations that upgraded their zinc extraction systems last quarter. Book a FREE ore analysis and get your customized ROI projection within 72 hours!

[Your Company Name] has deployed zinc extraction solutions across 14 countries since 2008. All systems come with a 5-year performance warranty and 24/7 tech support. Don’t let inefficient methods drain your profits – act before next quarter’s production cycle!

(zinc extraction from ore)

FAQS on zinc extraction from ore

Q: What are the main steps in zinc extraction from ore?

A: Zinc extraction typically involves crushing the ore, concentrating zinc minerals via froth flotation, and then roasting the concentrate to produce zinc oxide. The final step involves electrolysis or smelting to obtain pure zinc metal.

Q: How does froth flotation work in zinc ore processing?

A: Froth flotation separates zinc minerals from waste rock by exploiting differences in surface chemistry. Air bubbles carry hydrophobic zinc particles to the surface, forming a froth that is skimmed off, while hydrophilic impurities sink.

Q: What types of zinc ores are commonly processed?

A: The most common zinc ores are sphalerite (zinc sulfide) and smithsonite (zinc carbonate). Sphalerite is often processed via froth flotation, while oxidized ores like smithsonite may require leaching methods.

Q: What challenges arise during zinc extraction from ore?

A: Challenges include low zinc grades in ore, complex mineral compositions, and environmental concerns. Efficient separation during froth flotation and managing toxic byproducts like sulfur dioxide are critical hurdles.

Q: Why is froth flotation preferred for zinc ore concentration?

A: Froth flotation is cost-effective and highly efficient for separating fine-grained zinc minerals. It allows selective recovery of zinc sulfides from mixed ores, improving overall extraction yields.

Q: What environmental issues are linked to zinc processing?

A: Key issues include acid mine drainage from sulfide ores and emissions of sulfur dioxide during roasting. Modern plants use scrubbers and recycling systems to minimize environmental impact.

Q: How is zinc purity ensured after extraction?

A: Post-flotation, roasted zinc oxide undergoes electrolytic refining, where zinc is deposited on cathodes with >99% purity. Impurities like lead and iron are removed during earlier stages like slag formation.

Related Products

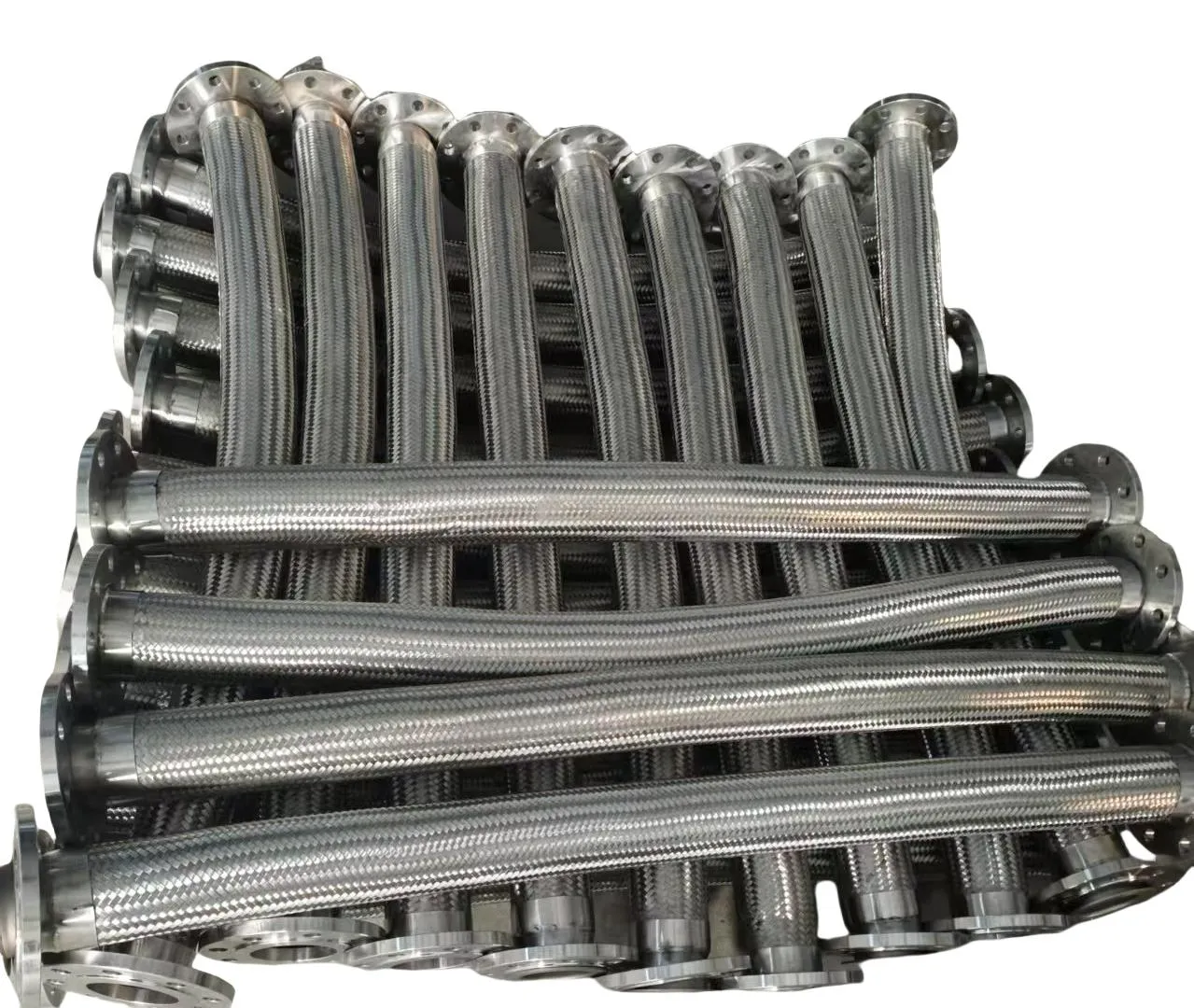

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.