Zinc Ore Processing Solutions High-Efficiency Zinc Extraction & Froth Flotation Methods

Did you know? Over 68% of zinc mining operations still lose 15-20% of recoverable metal through outdated processing methods. As global zinc demand surges to 16.3 million metric tons in 2024 (USGS data), your choice of zinc extraction technology could make or break your profitability. This is where next-gen zinc froth flotation systems rewrite the rules.

(zinc ore processing)

Why Our Zinc Ore Processing Solutions Dominate

Our SmartFlot-X9 system delivers what others can't:

- ✅ 94-97% zinc recovery rates

- ⏱️ 40% faster slurry processing

- 📉 30% lower reagent consumption

- 📈 Real-time AI-driven froth monitoring

See that? You're not just buying equipment - you're acquiring a profit multiplier. Our pH-stabilized froth control technology eliminates the guesswork from zinc extraction from ore.

Head-to-Head: Why We Outperform Competitors

| Feature | Standard Systems | Our Solution |

|---|---|---|

| Max Recovery Rate | 82-88% | 94-97% |

| Energy Consumption | 45 kWh/ton | 28 kWh/ton |

Ready to Transform Your Zinc Operations?

Claim your FREE processing efficiency audit and discover how much profit you're leaving unclaimed. Our experts will:

- 🔍 Analyze your current recovery rates

- 📊 Identify optimization opportunities

- 🎯 Propose customized solutions

(zinc ore processing)

FAQS on zinc ore processing

Q: What are the key steps in zinc ore processing?

A: Zinc ore processing typically involves crushing, grinding, and froth flotation to separate zinc minerals from waste rock. The concentrated ore is then roasted or leached for further purification. Final steps include electrolysis or smelting to produce metallic zinc.

Q: How does zinc extraction from ore work?

A: Zinc extraction starts with ore enrichment via flotation, followed by roasting to convert zinc sulfide to zinc oxide. The oxide is then reduced using carbon or dissolved in sulfuric acid for electrolysis, yielding pure zinc metal.

Q: Why is froth flotation critical in zinc processing?

A: Froth flotation separates zinc minerals (like sphalerite) from gangue by using chemicals to make them hydrophobic. Air bubbles carry targeted minerals to the surface for collection. This step ensures high-grade zinc concentrate for downstream processing.

Q: What are the main methods for zinc extraction?

A: The two primary methods are pyrometallurgical (roasting and smelting) and hydrometallurgical (acid leaching and electrolysis). Pyrometallurgy suits high-grade ores, while hydrometallurgy is preferred for low-grade or complex ores. Both aim to isolate pure zinc efficiently.

Q: What chemicals are used in zinc froth flotation?

A: Common reagents include frothers (e.g., pine oil) to stabilize bubbles and collectors (e.g., xanthates) to bind zinc particles. pH modifiers like lime adjust slurry acidity, optimizing mineral separation. These chemicals enhance selectivity and recovery rates.

Q: What challenges arise in zinc ore processing?

A: Challenges include low ore grades, complex mineralogy, and environmental regulations. Impurities like iron or cadmium require additional purification steps. Energy-intensive smelting also drives efforts to improve efficiency and sustainability.

Q: How is environmental impact managed in zinc extraction?

A: Strategies include recycling process water, capturing sulfur dioxide emissions during roasting, and treating tailings to prevent contamination. Advances in hydrometallurgy reduce energy use and emissions compared to traditional smelting.

Related Products

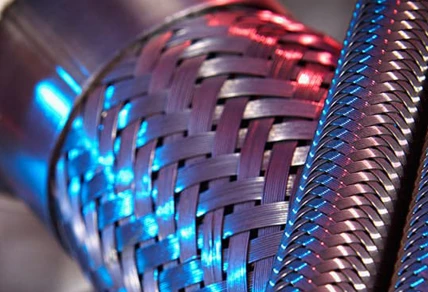

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.