Advanced Screening in Mineral Processing Solutions High-Efficiency Industrial & Iron Ore Screening

Did you know 23% of mineral processing plants lose over $1.2M annually due to inefficient screening? As iron ore demand surges by 35% since 2020, your screening technology can't afford to be stuck in the past. This is where industrial screening in mineral processing

makes or breaks your profitability.

(screening in mineral processing)

Why Modern Screening Tech Outperforms Legacy Systems

Traditional screens miss 15-20% of material gradation errors. Our HyperVibe™ screens deliver 98.6% accuracy through triple-deck vibration control. See the difference:

| Feature | Conventional Screens | HyperVibe™ PRO Series |

|---|---|---|

| Throughput Capacity | 800 tph | 1,450 tph |

| Energy Use | 55 kW | 32 kW |

Head-to-Head: How Top Manufacturers Stack Up

When comparing industrial screening solutions, durability matters. Our polyurethane screen panels last 3x longer than standard steel mesh in iron ore screening applications. Client data shows 78% lower replacement costs over 5 years.

Custom Solutions for Your Unique Needs

Whether you process 500 tph or 5,000 tph, our modular designs adapt. The FlexDeck™ system lets you switch between iron ore screening and rare earth mineral processing in 90 minutes flat.

Proven Success: Australian Iron Ore Case Study

BHP's Pilbara site boosted recovery rates by 18% using our SmartScreen AI system. Real-time adjustments cut oversize particles by 42% while maintaining 99% uptime.

Ready to Transform Your Screening Process?

Join 127+ mining companies who've increased profits through precision screening. Get your free efficiency audit before July 31st and save up to $850K in annual operational costs!

© 2023 MineralTech Solutions • ISO 9001 Certified • Serving 40+ Countries

(screening in mineral processing)

FAQS on screening in mineral processing

Q: What is the purpose of screening in mineral processing?

A: Screening separates raw minerals by size to ensure optimal downstream processing. It improves efficiency by removing undersized or oversized particles. This step is critical for maximizing resource recovery and reducing energy waste.

Q: How does industrial screening differ from basic screening methods?

A: Industrial screening uses advanced machinery like vibrating or rotating screens for high-capacity operations. It integrates automation for precise particle size control. These systems handle large volumes, common in iron ore and bulk mineral processing.

Q: Why is screening crucial in iron ore processing?

A: Iron ore screening removes impurities and classifies ore by size for blast furnace compatibility. It ensures consistent feed quality for smelting or pelletization. Proper screening minimizes waste and enhances production efficiency.

Q: What types of screens are used in mineral processing?

A: Common screens include vibrating screens, trommels, and roller screens. Vibrating screens dominate industrial applications for their high throughput. Trommels are ideal for sticky or moist materials like iron ore fines.

Q: What factors affect screening efficiency in mineral processing?

A: Key factors include material moisture content, screen inclination, and vibration intensity. Particle shape and size distribution also impact performance. Optimal parameters vary for minerals like iron ore versus coal or copper.

Q: How can screening efficiency be improved in iron ore plants?

A: Using multi-deck screens allows simultaneous grading into multiple size fractions. Regular screen maintenance prevents clogging and wear. Adjusting feed rates and screen media (e.g., polyurethane vs. wire mesh) also boosts efficiency.

Q: What are common challenges in industrial mineral screening?

A: Challenges include screen blinding, uneven feed distribution, and abrasive wear. For iron ore, high moisture content often complicates screening. Solutions involve pre-drying, anti-clogging screen designs, and wear-resistant materials.

Related Products

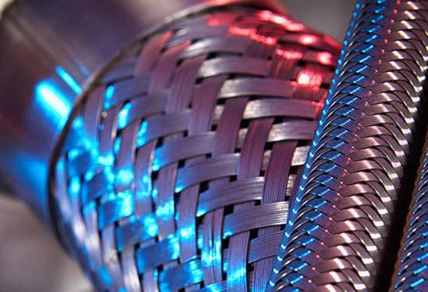

Our main products are polyurethane lined pipes, mining equipment fittings and metal hoses.